The Power of BLE – Four reasons to get excited about new BLE technology inside the Panasonic Logiscend System

- Panasonic Blog

- 3 mins

With the fourth Industrial Revolution (Industry 4.0) hitting the 10-year mark, there is no shortage of IoT technologies available. In fact, the key to manufacturers’ success so far has been their ability to correctly integrate technologies such as such RFID, Wi-Fi, Bluetooth and Zigbee to solve their unique business workflows. And now there is Bluetooth Low Energy (BLE).

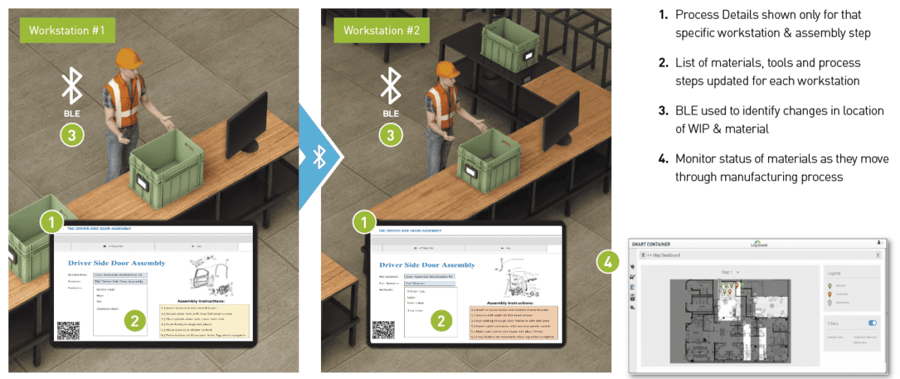

Here are four reasons why manufacturers should get excited about BLE within the Logiscend platform:

1. Location Accuracy to Within About a Meter*

BLE technology, with its highly accurate Real Time Location Service (RTLS) functionality, delivers powerful benefits. By incorporating advanced tracking techniques such as Angle of Arrival (AoA) and Angle of Departure (AOD), BLE devices can track assets within about a meter*. By incorporating BLE IoT hardware devices with Logiscend’s powerful rules engine and automated response workflows, users can configure automated actions to be taken based on an asset moving just a few feet. Imagine the injury prevention potential if you could trigger an automated response when two combustible objects come within a set proximity of one another. That’s just one use-case among a nearly endless list when high location accuracy is possible.

* Accuracy dependent on application.

2. Lower Power Consumption Than Traditional Bluetooth

To fully create a truly Smart Factory, IoT edge devices need to be low-maintenance and provide long battery life. If batteries need to be replaced too often, manufacturers can see their expected cost savings dwindle quickly. The development of BLE has enabled a vast array of new use cases and opportunities for implementing IoT solutions for manufacturers. By reducing the number of radio channels used on the Bluetooth communication band (2.4 GHz) from 79 1-MHz wide channels to 40 2-MHz wide channels, BLE’s power footprint is an order of magnitude smaller than traditional Bluetooth.

3. More Available and Affordable Connection to Existing Equipment

Smart Factories require bi-directional exchange of information between IoT edge devices, operational applications, and operators. Historically, manufacturing equipment has leveraged either proprietary or industry specific communication protocols such as Zigbee, OPC and PCI that are not readily available in consumer devices. Manufacturers have had to procure expensive devices to communicate with their equipment, and these devices become obsolete as soon as new machine protocols are created. With BLE, manufacturers can take advantage of widely available consumer-based devices such as smart phones, tablets, and convertible laptops, which keeps both procurement and maintenance costs down. Logiscend web-based applications enable users to leverage open standard communication protocols and widely available consumer hardware to limit infrastructure maintenance costs even further.

4. Cost Effective Integration with Consumer Devices

Many smart phones and tablets today use BLE to connect external devices such as headsets, car infotainment systems, smart watches, and many more. By leveraging the BLE technology that is widely adopted in the consumer market, manufacturers can capitalize on lower pricing due to economies of scale. With these common BLE IoT edge devices manufacturers can see a rapid Return on Investment opportunity when creating a Smart Factory.

The Panasonic IIoT Solution group identified the need for a flexible platform that could integrate different IoT technologies with the Logiscend system to enable the development of unique solutions for specific manufacturing use cases. BLE communications technology is now the latest example of Logiscend’s progress in supporting new IoT technology integration.

Logiscend with BLE Can Help you Find, Manage and Visualize Assets Within Your Facility

Logiscend already supports a wide range of manufacturing operational workflows including Asset Tracking, Part Picking/Kitting, Work Instructions and Part Replenishment. The addition of BLE makes the overall solution even more powerful. You can now configure automated workflows triggered by assets moving just a few feet. Quickly optimize manufacturing environments to increase throughput, reduce defects, and improve visibility of your critical processes.

Get the Hardware, Software and Professional Support You Need for IIoT Implementation.

Panasonic Logiscend has everything you need to successfully make the move to Smart Manufacturing.

Learn more about all the Panasonic Logiscend applications right here.