Enhance your manufacturing execution system (MES) and optimize your production line

Logiscend by Panasonic helps ensure the right parts are in the right place when you need them. Improve productivity, reliability and gain insight into your sequence efficiency with seamless integration with your existing Enterprise Resource Planning (ERP) / Manufacturing Execution System (MES)

Some of the key benefits:

- Focused on improving Availability, Performance and Quality with a modular solution

- Improve Throughput and Productivity with easily changeable installation configurations

- Production line data collection with real-time and historical data

Our modular approach doesn’t require a complete overhaul of your existing systems and can be implemented in stages allowing for rapid enhancements that support long-term initiatives.

Logiscend has a proven track record with years of use in enterprise just-in-sequence assembly lines — proven to be reliable, reduce costs and improve workforce accuracy, easily scalable for multiple assembly lines and plant locations.

Why add Logiscend to your MES/ERP?

- Hardware that interacts with the operators and collects data based on human interaction. This is something a big enterprise system typically won’t support

- Ability to customize the system to optimize a specific material flow problem

Improve production line material flow in 6 simple steps. Download the guide.

Why Logiscend?

Quick installation process

The Logiscend material flow management solution is easy to install, easy to configure and easy to fit into your budget. Panasonic has done the hard work up front — creating the Logiscend software platform with integrated hardware — so specifying and installing the entire system for your plant is both fast and easy, compared to custom-built solutions.

We take pride in our unique ability to get the material flow management system online quickly, keeping your downtime to the bare minimum. The Logiscend solution integrates seamlessly into your plant IT infrastructure, and the system’s wireless capability makes reconfiguring the lines a snap, reducing downtime even further. Once the first system is in place, additional systems are even easier to install, allowing you to stretch your budget further. Find out how long your system installation will take.

Improve workforce accuracy

Our research into plant productivity trends shows that worker turnover is affecting production, and new worker training is consuming valuable time and resources.

With Logiscend, your workforce will benefit from interactive displays, dynamic instructions, and ease of use — with low to little training required. Your bottom line will benefit from reduction in errors, improved production, and significantly reduced training time. See how the Logiscend Kitting applications improved worker efficiency.

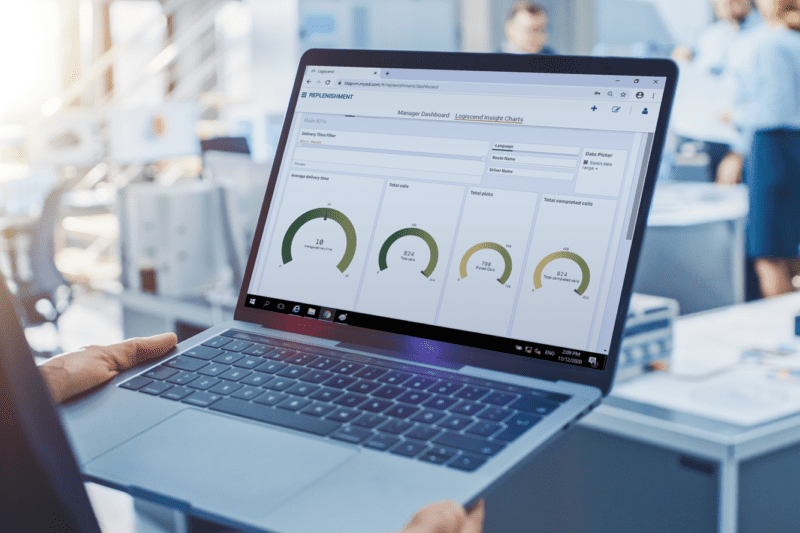

Better visibility to your assets and processes

Ditch the paper labels and enter the world of Industry 4.0. Logiscend is a data-driven system, and data is the key to Industry 4.0. Our constantly evolving software and active/passive RFID technology — such as the interactive, paperless display tags — allow full advantage of location-aware assets with visibility over multiple production years.

Our Replenishment solution accounts for missing and broken parts — a true just-in-sequence solution — and the threshold alerts eliminate the need to have workers walking the line to check inventory. Our Asset Tracking and Smart Container applications provide visibility of material throughout the entire manufacturing process, allowing you to trace assets and containers over time, and benefit from automatic data collection. The Logiscend system can help your company save substantial amounts in missing parts and extra labor by streamlining your operations, reducing waste and optimizing labor.

Reduce the complexity in your factories

Enterprise manufacturing facilities have too many moving parts to easily accommodate multiple custom applications from small integrators. Panasonic can help with Logiscend: one reliable platform for material flow management which includes hardware, software, and the engineering services to provide the best solution for your specific needs.

One platform means that all of the lines in the factory and all of the factories in your network can be integrated on one software platform, with easy-to-use dashboard metrics at line level and seamless integration with your corporate ERP/MES system. One platform means less work for your IT Department, and less training required for your workforce. One platform means a win for Industry 4.0 manufacturing optimization — especially since it is supported by the engineering prowess of one of the most respected companies in the world. Panasonic is reinventing the factory with deep system expertise, legendary reliability and Logiscend. See how one platform can benefit your factory.

Contact our Solutions Engineers for more information

Please submit the following information to chat with our solutions team. We’ll have a short discussion about your current challenges and help identify if there’s a Logiscend solution that can help. Fields marked with an * are required