The Flexible Alternative to Pick-to-Light

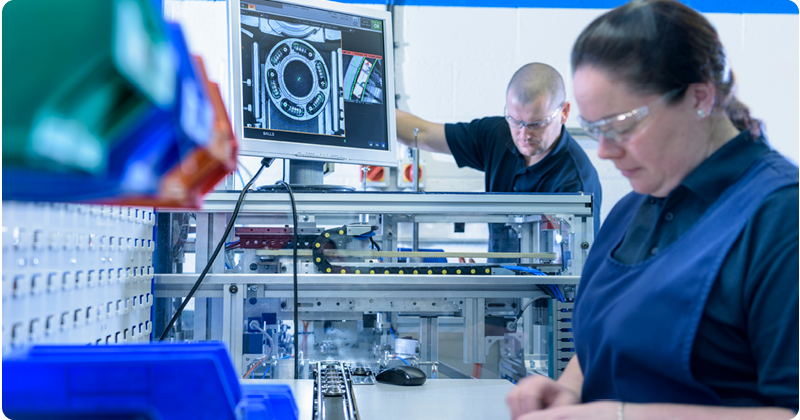

An easily integrated, wireless system that produces accurate results, collects vital data, and improves material workflow in all types of MES environments.

Watch this 2-minute video for a quick overview that highlights the enhanced benefits benefits of dynamic work instructions, wireless flexibility and detailed data collection.

Flexible

No wired infrastructure - easy to modify for part and line changes

Accurate

Detailed work instructions delivered to the line

Data Collection

Collect every aspect of line productivity in a central database

Simple Deployment

Integrates with most MES Systems

Support

US-Based support team for implementation and ongoing service

Ready to learn more?

The Logiscend™ industrial IoT solution for intelligent material flow management provides a scalable platform that can quickly enhance your pick efficiency and provides a path for longer term growth and efficiency improvement across your production line.

The Logiscend solution consists of:

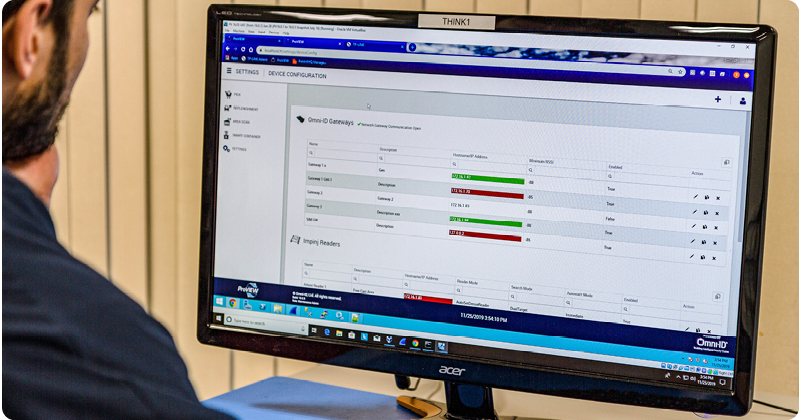

- The software platform for integration with multiple workflows and facilities

- The wireless hardware for tracking and tracing assets

- The engineering support to design and implement the best solution for your needs

Panasonic’s unique modular approach to material flow management goes far beyond a standard pick to light system. The Logiscend platform integrates seamlessly with your corporate ERP/MES system, aids in data collection and provides a flexible platform that evolves as your line complexity grows and changes.

Logiscend has a proven track record with years of use in enterprise just-in-sequence assembly lines — proven to be reliable, proven to reduce costs and improve workforce accuracy, proven to be easily scalable for multiple assembly lines and plant locations.

Contact our Solutions Engineers to learn more

Please submit the following information to chat with our solutions team. We’ll have a short discussion about your current challenges and help identify if there’s a Logiscend solution that can help. Fields marked with an * are required