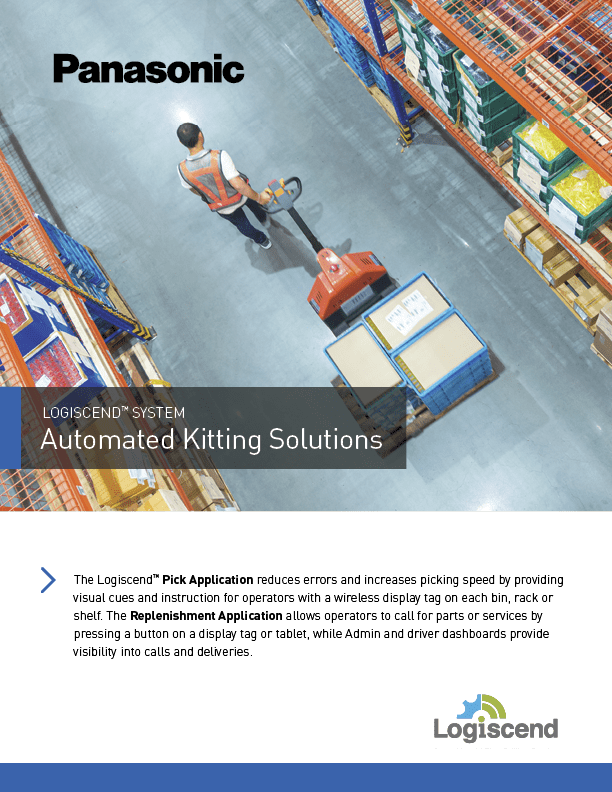

Automated Kitting Solutions: Pick

One platform to handle all material flow

Getting the right parts to the right place at the right time in any factory starts with ensuring an accurate picking or kitting of those parts from the warehouse, line-side or other “shopping” location. With the Panasonic Logiscend Pick Application, we can bring your process into the IoT future.

Paper-based processes are highly error-prone and inefficient when it comes to ensuring the correct parts are located and selected manually by operators. Pick-to-light systems are time-consuming to install and expensive to reconfigure. The Logiscend Pick Application ensures an accurate and efficient process by providing visual cues and instruction for operators for each job with a wireless visual tag at the pick location. Talk to our team for full details.

Standard work: No training or re-training necessary

This simple and intuitive system includes visual indicators and instruction right on the visual display tag, and requires little to no training — providing for ease of system and/or new operator deployment.

- Screen instructions automatically direct operator of pick quantity and location

- Eliminates need for hand-held equipment or fixed readers

Visual factory: Real-time instruction and indicators for operators

The Logiscend Pick Application improves the communication of information and the accuracy of

the process.

- Visual tags provide 2-way communication with both visual instruction and operator feedback to confirm the pick

- Address process issues in real-time with dynamic instructions

Re-configurable, simple wireless deployment

Logiscend requires no wired infrastructure. Unlike complex pick-to-light options, the Logiscend Pick Application provides simple installation and is re-configurable where you need it — when you need it.

- Easily create temporary Pick locations based on demand and volume

- No hard-wired infrastructure is required, allowing for line rebalancing

Monitor KPIs: Manager dashboards

Dashboards provide pick rates, delivery metrics and alerts to optimize process performance in real-time.

- Analyze bottlenecks to improve throughput

- Balance processes and eliminate waste (Muda)

- Connects easily to existing ERP/MES/WMS systems

Logiscend combines the strengths of RF picking, visual logistics, and traditional pick-to-light systems to improve accuracy to 99.97%.

We have worked hard to build a common platform for enterprise manufacturing. We believe that the Logiscend system creates a new paradigm for the manufacturing process:

- The visual cues of paper labels — without the paper

- The tracking capabilities of passive and active RFID — enhanced with two-way communication

- The powerful Panasonic IIoT software platform to enable the digitization and manufacturing optimization of Industry 4.0.

And at the end of the shift, your assets will be in the right place at the right time to position your factory for even greater success.

Professional services

Panasonic is your trusted integrated solutions partner, committed to helping improve your organization’s key performance indicators (KPIs), including productivity, quality, and cost targets. Our ultimate goal — enterprise-wide operational excellence. We offer a full suite of services which can be individually customizable to provide all support necessary for a successful program.

Planning

Proper site planning and preparation is critical to large-scale equipment installation. From preliminary designs, to complete implementation specifications and solution testing, the Panasonic Logiscend Professional Service Group is ready to support your efforts. We will consult with you to understand your workflow, then design the right hardware and software solution for your facility. We can help you achieve your strategic objectives and assist in configuring a material flow management solution that meets your goals.

Installation & implementation

Our Installation & Implementation Services help you deploy the Logiscend System with minimal disruption. Services range from project management, hardware and software installation support, IT integration, system setup and configuration, user and administrator knowledge transfer and training, as well as user acceptance test supervision and documentation. We utilize the Project Management Body of Knowledge (PMBOK) guide and standards.

Maintenance & support

Our expert maintenance and support team are dedicated to maximizing your investment and helping you drive performance and usability. In addition to repair services, we offer remote equipment monitoring and preventive maintenance. Your annual subscription entitles you to the latest software releases ensuring you are up to date with new features and security enhancements.

Engineering services

We have a team of experienced hardware and software engineers that can be deployed should your workflow require a unique implementation. We will work with your team to document scope, cost and an implementation timeline. If your organization has specific goals or conditions which must be met, our Engineering Services department will consult closely with your team to design and implement the best and most appropriate solution for your needs.

Are you looking for more information about Panasonic IIoTS solutions?

Our professional team is ready to help. Send your questions and a Solutions Engineer will contact you shortly.