3 Reasons to Take the Paper out of your Processes

- Panasonic Blog

- 4 mins

“Paperless Manufacturing” starts with moving data from pages and labels to screens but goes much deeper to include automated data capture, industrial touchscreens, and direct connections between systems to avoid handling completely. Where are you on the spectrum?

Why Paperless Manufacturing Matters So Much to So Many

It’s simple. Manufacturers who have replaced manual, paper-based processes with digitized systems report three very measurable benefits to their businesses:

1. Lower Costs

Going paperless doesn’t just help save the environment it can save a lot of money. Automated business processes and workflows using optical character recognition and direct connections between systems reduce the costs of consumables, waste, and errors. While some of these savings are more obvious, the labor savings of the paperless manufacturing may be a pleasant surprise:

- When status reports are accurate and automated, planners don’t waste time checking and reporting on job status at the beginning and end of each shift.

- When detailed documents are searchable in a shared database, no one must store or sift through piles of paper.

- Eliminating the printing, maintenance, production and sharing of paper documents and labels throughout a manual production environment not only saves the cost of paper, ink, and labor but it also frees up the time of workers across the operation and allows them to focus on more profitable activities.

2. Improved Quality

Optimizing manufacturing processes to reduce the quantity and severity of quality events is critical, but many manufacturers continue to rely on paper-based systems that can make the impact and complexity of any quality event much worse. Paper-based processes and production records are simply less efficient and more prone to errors that can increase production deviations, delay product releases, and decrease consumer satisfaction.

Digital systems help manufacturing workers get production right the first time. Replacing paper with data:

- Helps eliminate errors and effort wasted during manual data entry processes

- Minimizes inspection and review

- Focuses people on the work right in front of them.

3. Easier Innovation

“Doing more with less” has been the anthem of so many businesses for decades, and innovation is the key to achieving this goal of improving productivity while maximizing resources. Innovation comes from sharing ideas. A paperless manufacturing environment allows information to flow faster and more reliable between people, departments, and functions throughout your entire company.

You can help employees generate fresh ideas that boost productivity and profitability. With a paperless environment, workers can:

- Collaborate freely

- Access accurate data

- Coordinate revisions

- Maintain a sharable history

Start Simple. But Start Now.

While it’s easy to see the upside of digitization, it’s understandable so many are hesitant to embrace the change to a completely paper-free workplace over night. It’s easier when you first experience the benefits for yourself.

While implementing a paperless strategy system wide can be most effective and beneficial, you can also implement paperless technologies and workflows piece by piece. In fact, the savings generate with each initiative, can both justify and finance further efforts. Logiscend offers modularity in our smart manufacturing solutions for just this reason. Some customers integrate all our applications, while other start with the ones that will drive the most benefits right away.

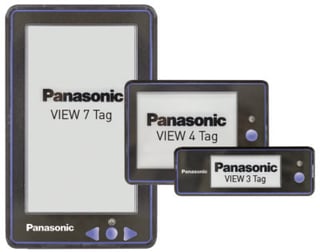

Panasonic VIEW Tags Beat Paper Any Day

Here are 4 ways to start your move to paperless manufacturing:

Here are 4 ways to start your move to paperless manufacturing:

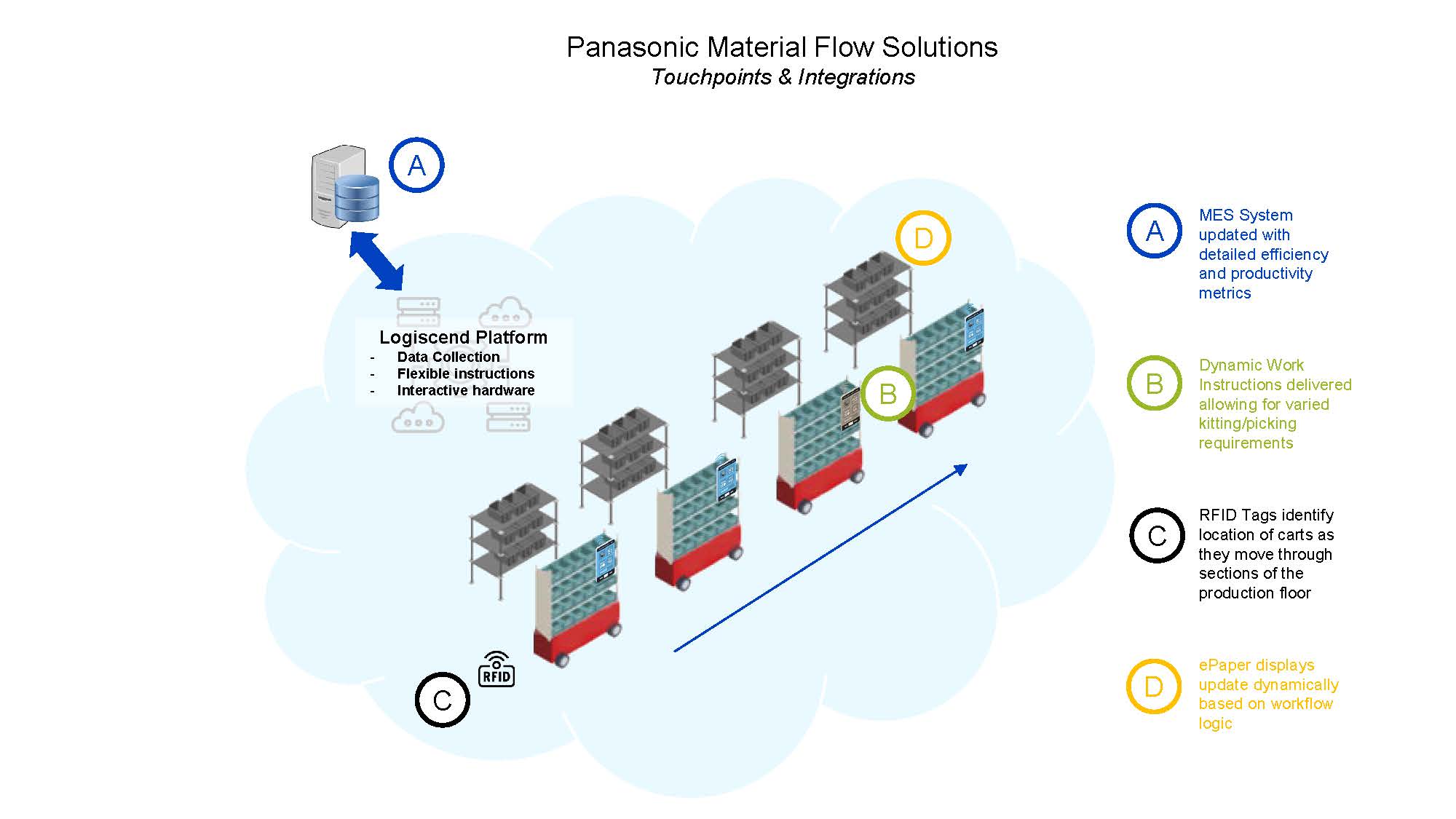

1. Panasonic Logiscend Pick Application

How just-in-sequence manufacturers get the right part to the right place at the right time. Panasonic VIEW tags provide wireless, two-way communication—operators can receive pick instructions on the e-paper display that tells them quantity to pick and bin location and they can acknowledge the pick with a simple button press on the tag. The system increases pick accuracy and reduces training and configuration time.

2. Panasonic Logiscend Replenishment Application.

The smartest way for high-volume manufacturers to build a fast, smooth, and highly accurate parts replenishment process that is entirely paperless. Wireless Panasonic VIEW tags in production enable operators to send replenishment requests directly to handlers, VIEW tags in the warehouse visually signal handlers to make the process even faster, and manager dashboards provide visibility to bottlenecks and improvement opportunities.

3. Panasonic Logiscend Smart Container Application

A paperless solution to track the location, contents and status of assets and containers cycling through process and inventory while providing operator instructions. Panasonic VIEW Tags and Logiscend Software provide a wireless, paperless, IIoT solution that is faster, more cost efficient and greener than paper labels.

4. Panasonic Logiscend Work Instructions

You can enable timely and accurate operator instruction and feedback within complex manufacturing environments with this wireless, paperless, IIoT solution that optimizes compliance and training by providing operator instructions electronically. Information can be updated instantly with Logiscend Software according to location, quality issues or changes in workflow.