Press Release: Panasonic Logiscend Opens New Facility with Onsite Testing, Production Simulation, and Administration Capabilities

- Panasonic PR

- 2 mins

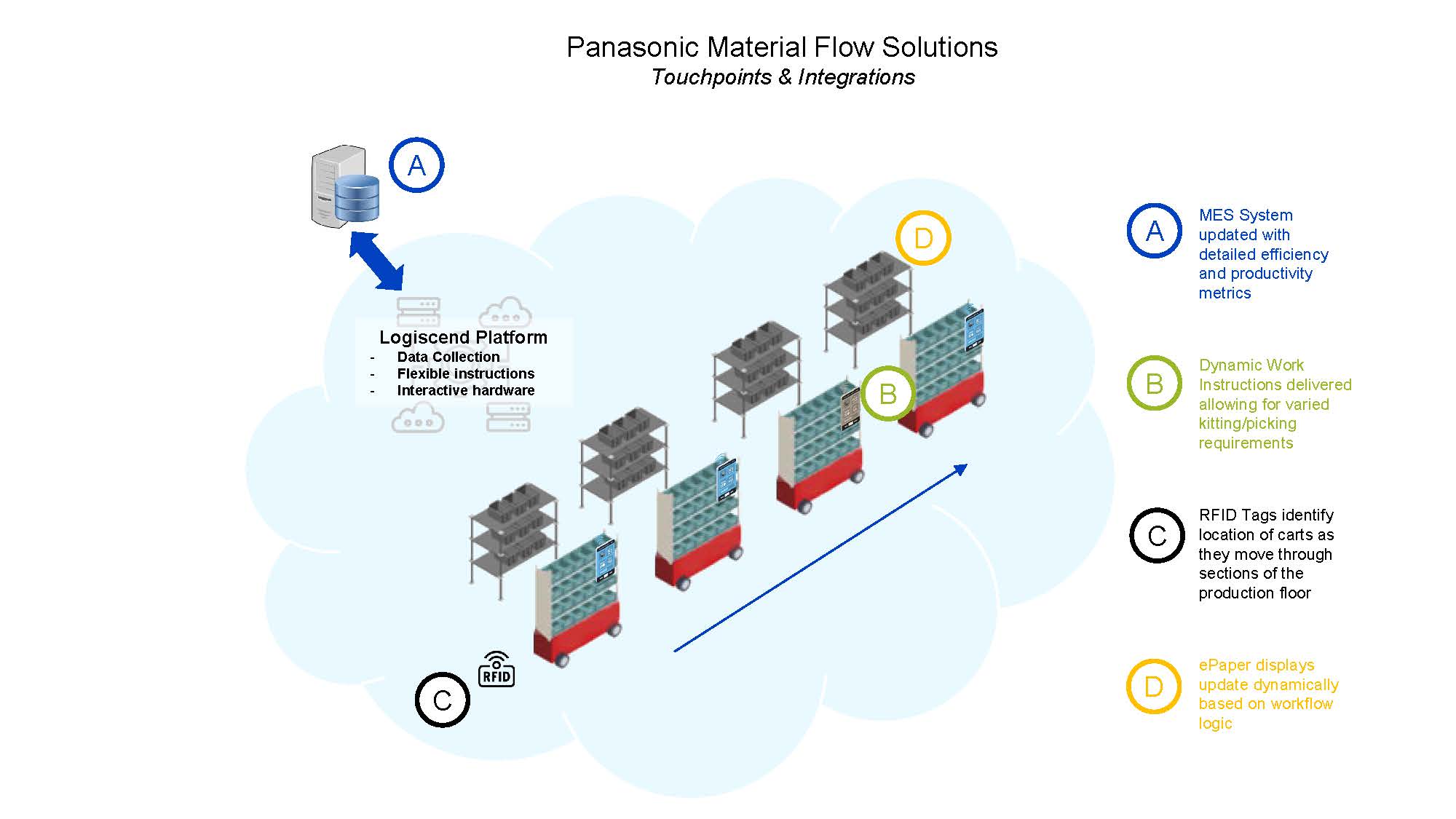

Panasonic demonstrated its Logiscend system with state-of-the-art tracking technologies, utilizing IIoT devices and RFID for superior material flow and asset tracking.

ROCHESTER, N.Y., January 16, 2025 — Panasonic Industrial IOT Solutions Group, a division of Panasonic Corporation of North America, has moved to a new facility that includes an extensive production line testing area, allowing Panasonic to design, engineer, and test solution enhancements for manufacturers without disrupting current production lines.

Based in Rochester, NY, the new facility allows for testing and development of a wide variety of signaling and tracking systems in simulated real-world scenarios. With a focus on performance and quality, Panasonic’s engineering team works directly with manufacturing production teams to identify, test and model solutions endeavoring to improve overall equipment effectiveness and optimize material flow.

“Moving to this new facility simplifies and streamlines collaboration, rapid testing and implementation planning before customers adopt a new solution,” said Michael Buonaccorso, Group Manager, Panasonic Industrial IOT Solutions. “While our teams require a significant amount of collaborative on-site work, being able to evaluate scenarios in our brand-new Customer Experience Lab without disruption to our clients’ workflow is a huge advantage.”

The new facility allows the Panasonic software, quality, and application engineering teams to work together in one cohesive environment to develop solutions with improved efficiency.

Panasonic’s Logiscend system is built on a platform which focuses on manufacturing’s core components (picking, replenishment, asset tracking, and work instructions). The open floorplan and ease of collaboration in the new facility allows for more efficient modification and implementation of these core components, combining technical and engineering systems that can be assessed offline to minimize disruption for the benefit of customers’ production processes.

Panasonic’s Logiscend system has a proven track record of success. By leveraging offline planning and testing, a large automotive Tier 1 supplier was able to transform its parts replenishment process with minimal disruption and facilitated easy inline implementation. Shifting from an outdated paper-based Kanban system to Panasonic’s Logiscend system, created real-time electronic communication through e-paper visual tags for parts requests, which significantly enhanced efficiency and reduced overall costs.

Panasonic Logiscend

Panasonic Logiscend is an innovative material flow management platform, that leverages the power of Industrial Internet of Things (IIoT) devices to optimize asset tracking and production processes. Designed to enhance visibility, accuracy, and efficiency in manufacturing operations, Logiscend seamlessly integrates into existing systems, providing real-time tracking and data insights. With scalable solutions tailored for the automotive industry and beyond, Panasonic Logiscend empowers manufacturers to streamline their workflows, reduce errors, and achieve greater operational excellence. Learn more about the Logiscend platform at Logiscend.panasonic.com.

About Panasonic Corporation of North America

Newark, NJ-based Panasonic Corporation of North America is a leading provider of Consumer Lifestyle technologies, as well as innovative Smart Mobility, Sustainable Energy, Immersive Experiences, and Integrated Supply Chain solutions. The company is the principal North American subsidiary of Osaka, Japan-based Panasonic Holdings Corporation. One of Interbrand's Top 100 Best Global Brands of 2023, Panasonic is a leading technology partner and integrator to businesses, government agencies and consumers across the region.

Media Contact:

Betsy Sagges (Panasonic Corporation of North America) betsy.sagges@us.panasonic.com