The Hidden Cost of Paper in Modern Manufacturing

- Panasonic Blog

- 3 mins

One of the main tenets of the Smart Factory or Industry 4.0 is eliminating paper in manufacturing. When you reveal the hidden costs of facilities relying on paper, it’s easy to see how digital manufacturing leads to improved quality, increased flexibility and reduced costs.

How much does printing your paper labels really cost?

The success of every business and every business process is about return on investment. While we are all looking for profit in the end, there is always a cost of entry up front. The trick is realizing that some of our decisions cost us more than we calculated. Printing paper labels has costs at every turn.

What’s the cost of printing labels wrong?

Industry averages say that it costs $10-20 to reprint a roll of labels. That’s just counting the label material and the labor. You can spend up to $100 more to identify and fix issues related to incorrect printing and scanning. You can see the hidden costs of printing errors, but that’s just the beginning.

What’s the cost of printing labels right?

If labels print correctly but containers and or parts are labeled wrong, it’s difficult to find parts, keep production flowing and deliver a quality product on time. If labels are incomplete, it’s harder to track inventory automatically and you have to rely on time- and cost-consuming manual entry. And labels are messy and often come loose and end up on the factory floor! That’s where even more errors can occur.

We have not even discussed environmental costs. Every roll of labels carries with it the economic and environmental impact of the label material itself, all the shelving and shipping packaging, and the printing consumable costs.

What’s the value of switching from paper labels to smart tags?

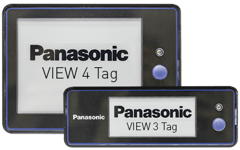

Electronic smart tags can change in an instant for quick, accurate reconfiguration of manufacturing, picking and warehousing space. Electronic smart tags can provide consistent, up-to-the-minute instructions to handlers and operators. And electronic smart tags can report tag and container location and status instantly to management.

Paper will never be this smart.

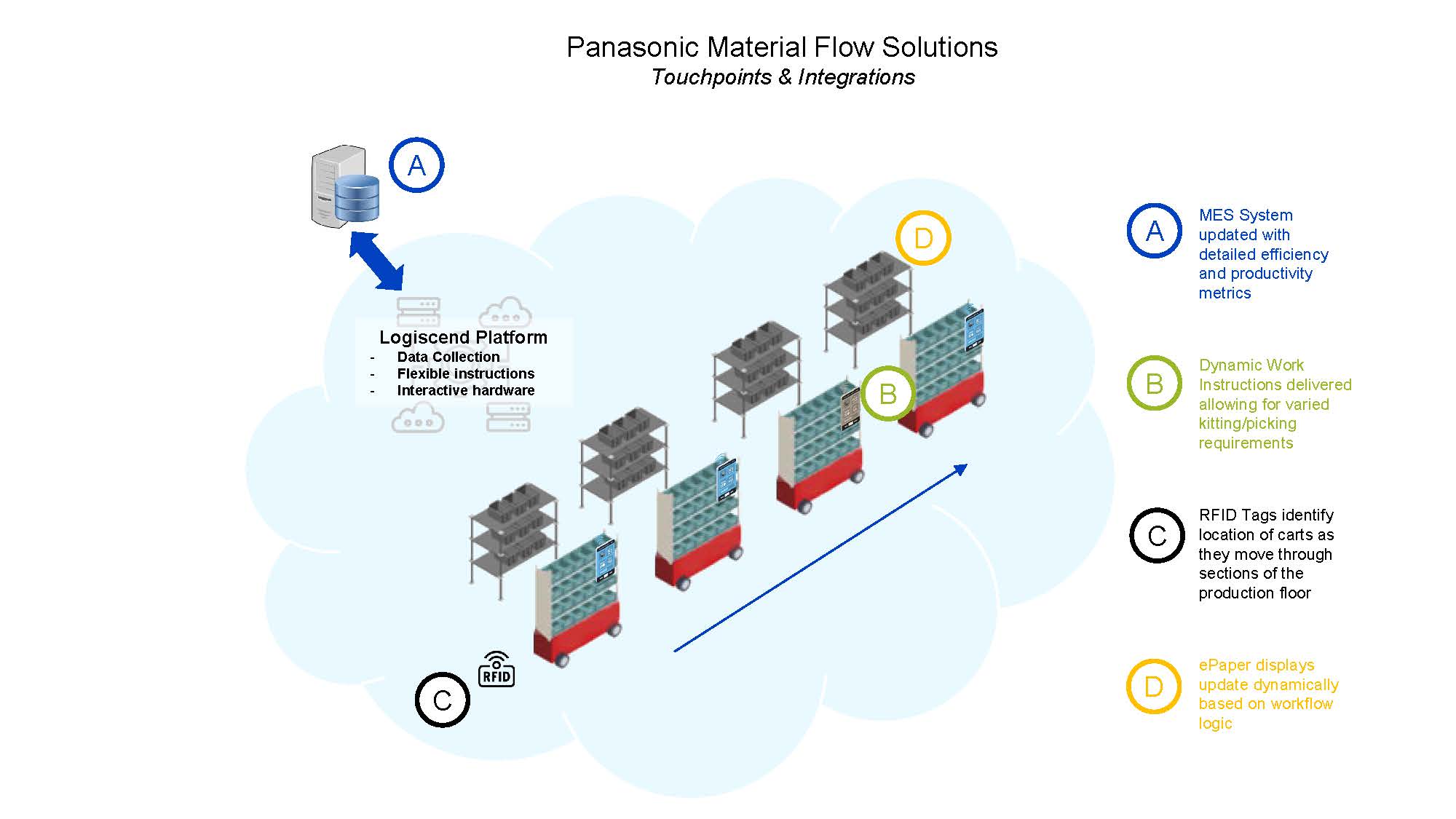

The Panasonic Logiscend System is an IIoT material flow management solution that combines the power of wireless Panasonic VIEW Tags with Logiscend hardware and software to help complex manufacturing operations get the right parts, to the right place, at the right time. The complete Logiscend solution includes applications for Picking, Replenishment, Smart Containers, Asset Tracking and Work Instructions.

The Panasonic Logiscend System is an IIoT material flow management solution that combines the power of wireless Panasonic VIEW Tags with Logiscend hardware and software to help complex manufacturing operations get the right parts, to the right place, at the right time. The complete Logiscend solution includes applications for Picking, Replenishment, Smart Containers, Asset Tracking and Work Instructions.

Logiscend can take the paper in your process and turn into productivity.

Here are just three examples:

The Panasonic Logiscend Pick Application is a hands-free, paperless process that requires minimal training and improves picking speed and accuracy. The combination of IoT and e-Paper VIEW Tags provides 2-way communication where operators receive visual instructions such as quantity and cart bin location and then confirm finished pick.

The Panasonic Logiscend Smart Container Application is the smartest way for manufacturers with containers cycling through process and inventory to track their location, contents and status while providing operator instructions. Panasonic VIEW Tags and Logiscend Software provide a wireless, paperless, IIoT solution that is faster, more cost efficient and greener than paper labels.

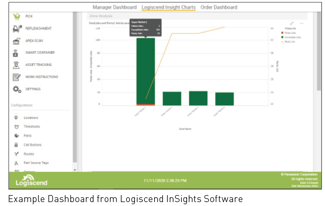

Every Logiscend application provides management with accurate and automated data that’s impossible with paper. Real time visualization through manager dashboards and seamless integration with your ERP/MES systems and helps reveal needed action in real time.

Every Logiscend application provides management with accurate and automated data that’s impossible with paper. Real time visualization through manager dashboards and seamless integration with your ERP/MES systems and helps reveal needed action in real time.

Paper is so last century

For years, we have all been seeing less and less paper in our homes and our factories. But now that we can see the true cost of working in a paper-based environment, there is a drive to make changes even faster. As companies evolve, they need to identify cost-effective solutions and strategies that balance today’s needs with tomorrow’s performance requirements. One perfect example is the move from paper-based systems to Panasonic VIEW tags applications.

Learn more about all the Panasonic Logiscend applications right here.