How to Successfully Implement Industrial IoT in 5 Steps

- Panasonic Blog

- 4 mins

While more manufacturers are chasing the promise of IIoT and the transformation that Industry 4.0 or Smart Manufacturing can bring, the overall success rate of IIoT projects is low. This is because it can be difficult to get a plant-wide rollout or even a proof-of-concept program started without key factors in place from the start.

While more manufacturers are chasing the promise of IIoT and the transformation that Industry 4.0 or Smart Manufacturing can bring, the overall success rate of IIoT projects is low. This is because it can be difficult to get a plant-wide rollout or even a proof-of-concept program started without key factors in place from the start.

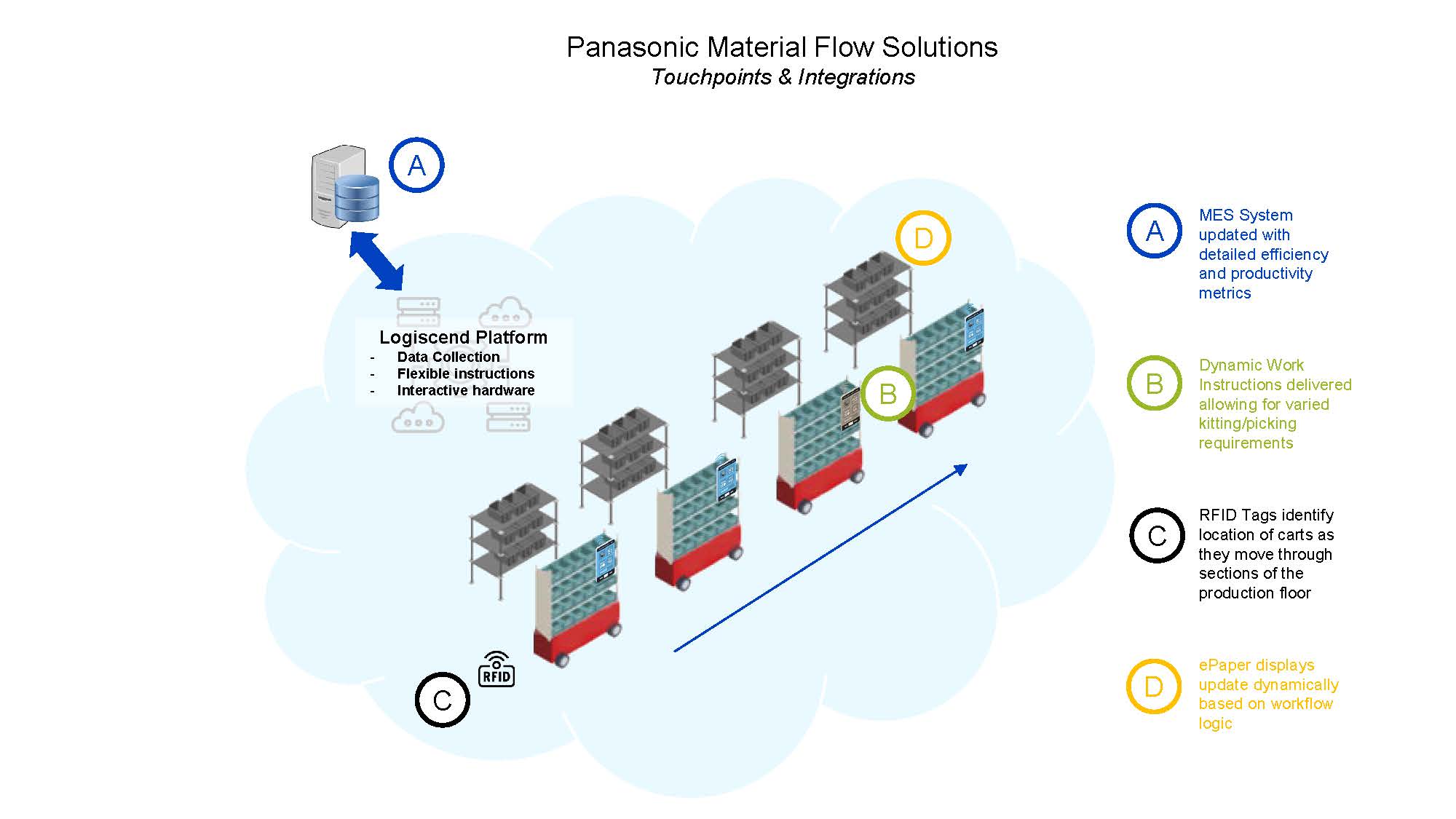

The Panasonic Logiscend Professional Services Group has helped many manufacturers implement the Logiscend IIoT hardware and software solution for material flow management. As an example, a Tier 1 global manufacturer of auto seating systems and components implemented our Pick application in their kitting supermarkets at 11 of their facilities. The results were so positive — 50% labor reduction, 90% reduced training time, 99.8% pick accuracy, no more paper and printing — that they have since added the Logiscend Replenishment application to the facilities.

As we design and implement these IIoT solutions across varying industries, we have identified 5 key actions that were taken in every successful implementation. Here is how to best achieve success in your operations:

1. Secure Management Buy-in and User Engagement:

Because most IIoT projects include IT and business elements and have hiccups along the way, identify champions in both functions ahead of time so they can help remove barriers as they arise. It is also important to identify the customer champions who will be responsible for day-to-day project implementation. They should interact with multiple functions within the manufacturing site including the end-users who will be affected by the change. Once you identify the key users and seek their input, they can better support implementation and knowledge transfer.

2. Clearly Define the Project and the Success Criteria

It is imperative that all parties agree upon and document the scope, the problem being solved, and the way success will be measured. Value stream mapping is an efficient LEAN tool to help document and visualize the current and future state. This map should include goals and defined success criteria. You can also identify areas of waste and measure key criteria where improvements are needed. These often include time studies for setup, work processes, and training as well as number of defects and costs for material and labor.

3. Identify Roles & Responsibilities

Develop the implementation team of both employees and vendors, if being used, and create a matrix of team member names, contact information and areas of specific responsibility. Successful projects often use a RACI model to bring structure and clarity to the roles of team members. With RACI, each task has a person, or persons: Responsible for completing the task, Accountable to approve when the task is complete, Consulted to give input before the work is signed-off, and Informed on progress along the way.

4. Create a Project Plan That Looks Ahead

The importance of a project plan with tasks and dependencies and the ability to see the horizon cannot be overstated. Successful IIoT implementation requires a blueprint and step-by-step action plan. Your plan should include scheduled reviews for gathering criteria for when to go forward and be able to look ahead far enough into the future to anticipate potential issues. Plans like this enable you to put mitigations in place well before they are needed. This saves you time and money and is often the key to a successful implementation.

5. Plan to Share the Knowledge

Be sure to includes ample planning and effort to train and share the newly implemented IIoT process with all who are affected by the change. Just as key user engagement is critical at the beginning, it needs to be even broader as implementation gets closer to completion. Successfully leading others through change is not an easy task and proper planning for this task is just as critical, if not more, as the other 4 critical steps.

Professional Services Can Help with Every Step of Your Successful IIoT Implementation

Panasonic Logiscend will be your trusted integrated IIoT solutions provider. Committed to helping improve organizations’ key performance indicators (KPIs), including productivity, quality, and cost targets, our goal is nothing short of enterprise-wide operational excellence.

We offer a full suite of customizable services to help you improve material flow management:Planning—From preliminary designs to complete implementation specifications and solution testing. We will consult with you to understand your workflow, then design the right hardware and software solution for your facility to achieve your goals.

Installation & implementation—Helping you deploy the Logiscend System with minimal disruption through project management, hardware and software installation support, IT integration, system setup and configuration, user and administrator knowledge transfer and training, as well as user acceptance test supervision and documentation.

Maintenance & support—Our expert maintenance and support team are dedicated to maximizing your investment and helping you drive performance and usability. In addition to troubleshooting any issues, we offer remote equipment monitoring and preventive maintenance. Your annual subscription entitles you to the latest software releases ensuring you are up to date with new features and security enhancements.

Engineering services—Our team of experienced application engineers will work with your team to document scope, cost and an implementation timeline for the most appropriate solution that meets your needs and goals. Our engineering organization is deep in software and hardware IoT/RFID expertise.

Get the Hardware, Software and Professional Support You Need for IIoT Implementation.

Panasonic Logiscend has everything you need to successfully make the move to Smart Manufacturing.

Learn more about all the Panasonic Logiscend applications right here.