How to Use Industrial IoT to Overcome One of This Year’s Biggest Challenges

- Panasonic Blog

- 3 mins

Even though manufacturing activity is steadily increasing as we come out of the pandemic, factories are not easily finding sufficient skilled or even entry-level workers to bring production levels back to where they need to be. It is more important than ever to leverage the efficiency and productivity gains that can be achieved with smart manufacturing and IIoT.

The current worker shortage is not expected to disappear any time soon. According to a recent study published by Deloitte and The Manufacturing Institute, more than two million manufacturing jobs will go unfilled through 2030. By that time, the report warns, the worker shortage will not only hurt manufacturing revenues and production but could cost the US economy up to $1 trillion.

Compounding the current worker shortage, decreased production throughout the pandemic has resulted in shortages of critical components. For example, there is a shortage of semiconductors which are essential components in millions of products. Forrester predicts this semiconductor shortage could last until 2023 and will have a significant impact on electronics manufacturers’ supply chain and ability to meet consumer demand.

Manufacturers all know; when resources are tight, efficiency is key.

When it’s hard to fill let alone expand your workforce, you must maximize the quality throughput and productivity of every operation every day. And when inventory of high-demand products is low, you’re likely to be training the new employees you are able to find and asking existing workers to build things they haven’t touched before.

The good news is that worker shortages and inventory shortages both call for the same three solutions from manufacturers, and Logiscend can help with each one:

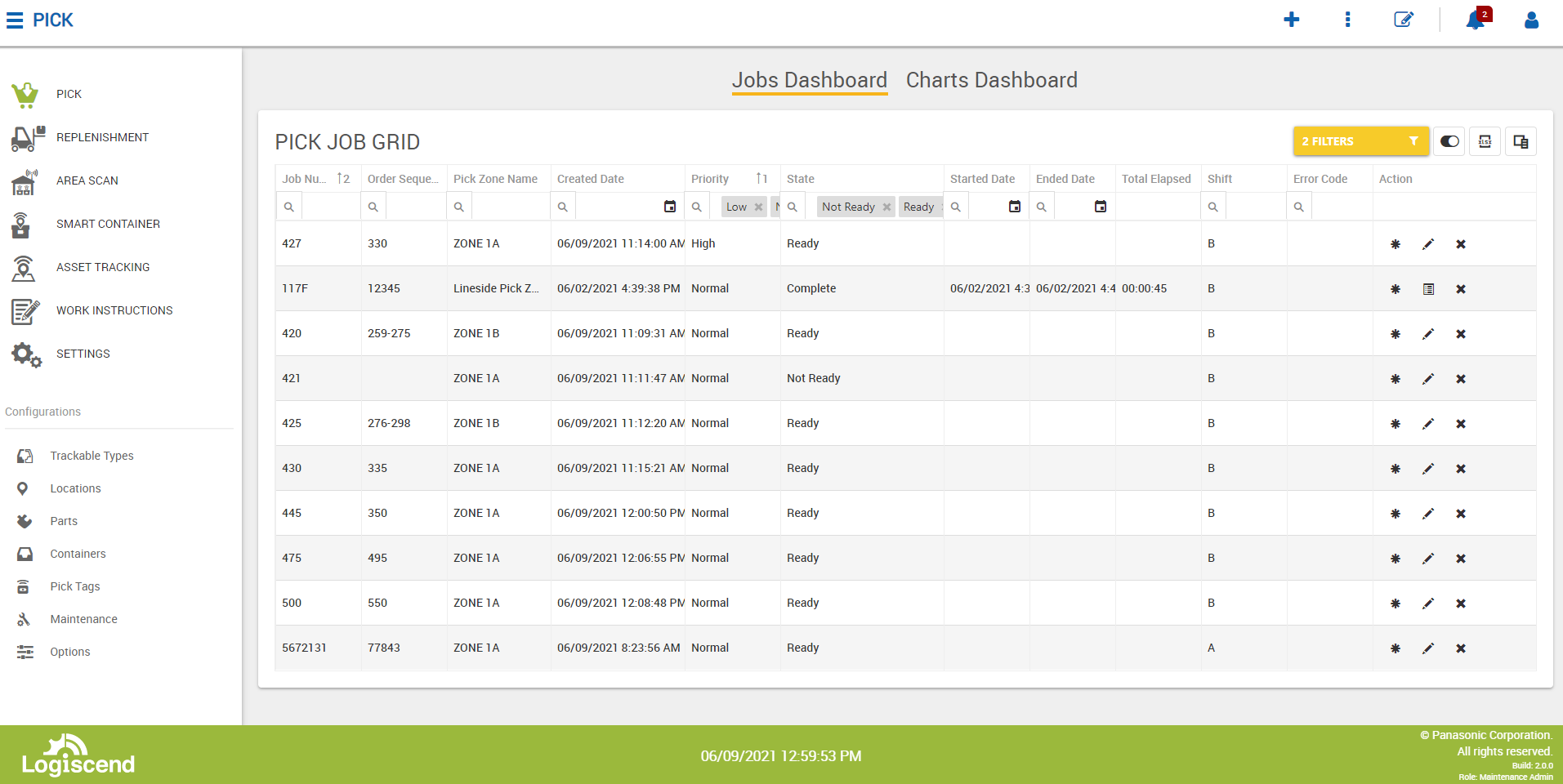

1. Increase Throughput by Optimizing Workflows and Reducing Errors

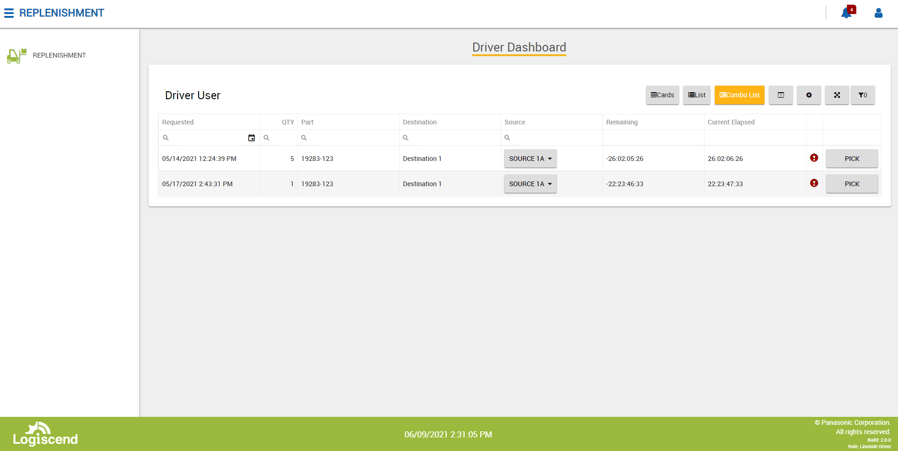

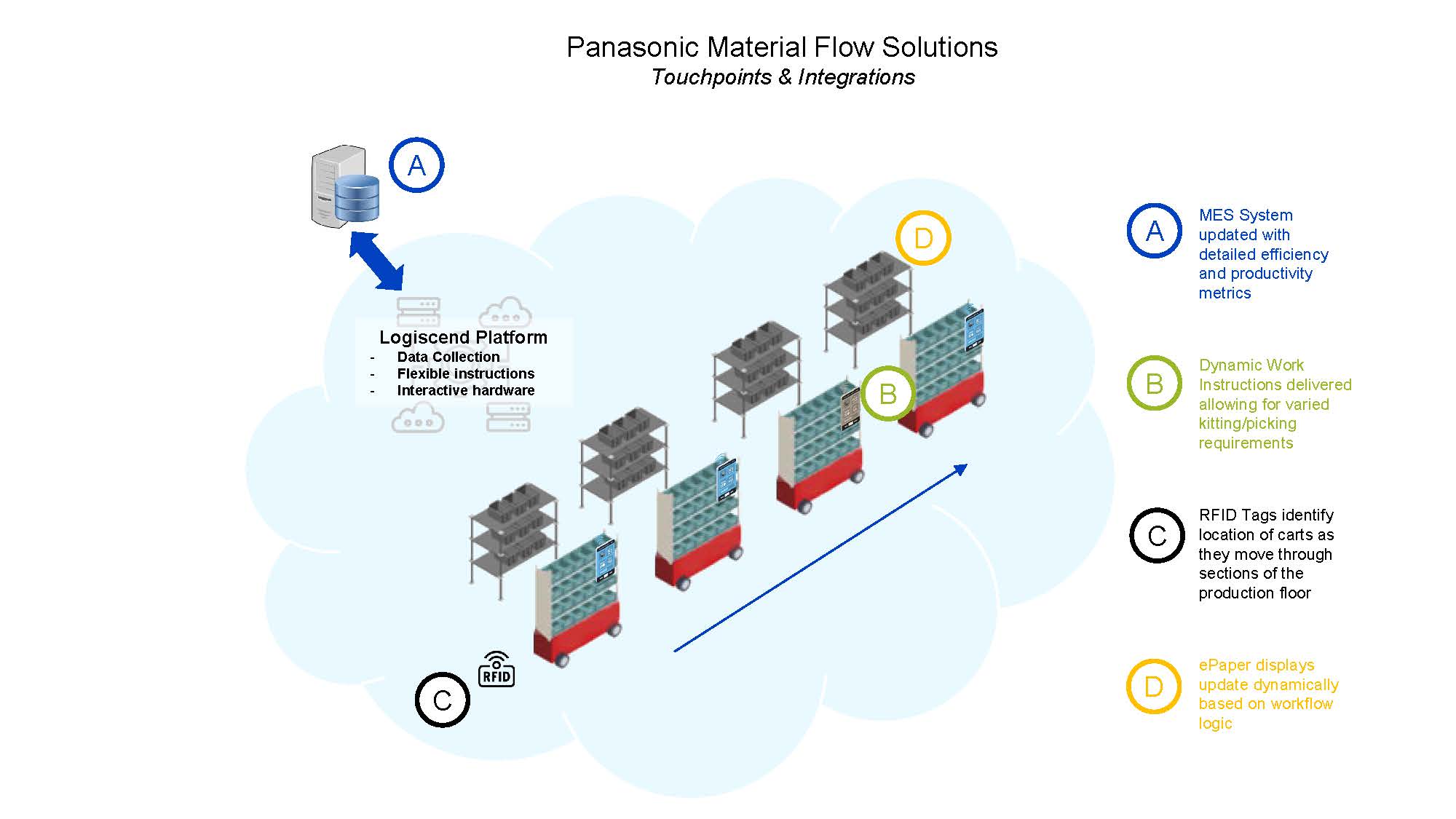

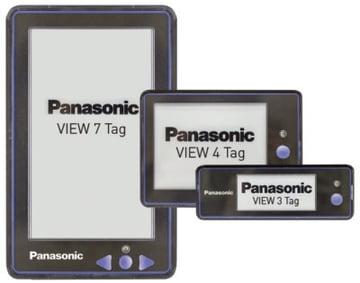

Increasing throughput and ensuring quality of finished products is even more essential during a worker shortage. Logiscend Pick, Replenish and Smart Container Applications all use Panasonic VIEW Tags that help get the right part to the right place at the right time. You might need to increase production but are dreading trying to staff a third shift. If you can use Logiscend IIoT to improve utilization from 75% to 85%, you may not need the third shift after all. One customer saved 10% on defects simply by picking the correct parts more often.

2. Accelerate Changeovers with Smarter Manufacturing

Inventory shortages and changes in customer demand both require the flexibility to instantly shift direction on the manufacturing floor. And if you are trying to do more with fewer employees, Logiscend Work Instruction, Smart Container and Asset Tracking applications can enable those changeovers with minimal worker and infrastructure disruptions. Wireless Panasonic VIEW tags provide dynamic, real-time work instruction with only the information necessary to successfully complete the new job, and each tag uses RF to report its status and location in real time. You can instantly change from producing one product to another and know that both the parts and instructions will get where they need to be for maximum productivity and accuracy.

Inventory shortages and changes in customer demand both require the flexibility to instantly shift direction on the manufacturing floor. And if you are trying to do more with fewer employees, Logiscend Work Instruction, Smart Container and Asset Tracking applications can enable those changeovers with minimal worker and infrastructure disruptions. Wireless Panasonic VIEW tags provide dynamic, real-time work instruction with only the information necessary to successfully complete the new job, and each tag uses RF to report its status and location in real time. You can instantly change from producing one product to another and know that both the parts and instructions will get where they need to be for maximum productivity and accuracy.

3. Reduce Training Time with Dynamic, Well-placed Instruction

Timely, accurate instruction isn’t just important during job changeovers, it’s essential when bringing on new employees—especially when those employees take so long to secure. The Logiscend Pick and Replenish Applications use Panasonic VIEW tags to provide visual cues and dynamic instructions to make training faster and more effective and the Logiscend Work Instruction Application is the smartest way to enable timely and accurate operator instruction and feedback within complex manufacturing environments. The wireless, paperless, IIoT provides clear operator instructions electronically and can be updated instantly.

Get the Hardware, Software and Professional Support You Need for IIoT Implementation.

Panasonic Logiscend has everything you need to successfully make the move to Smart Manufacturing.

Learn more about all the Panasonic Logiscend applications right here.