How to compute an ROI for material flow automation

- Panasonic Blog

- 5 mins

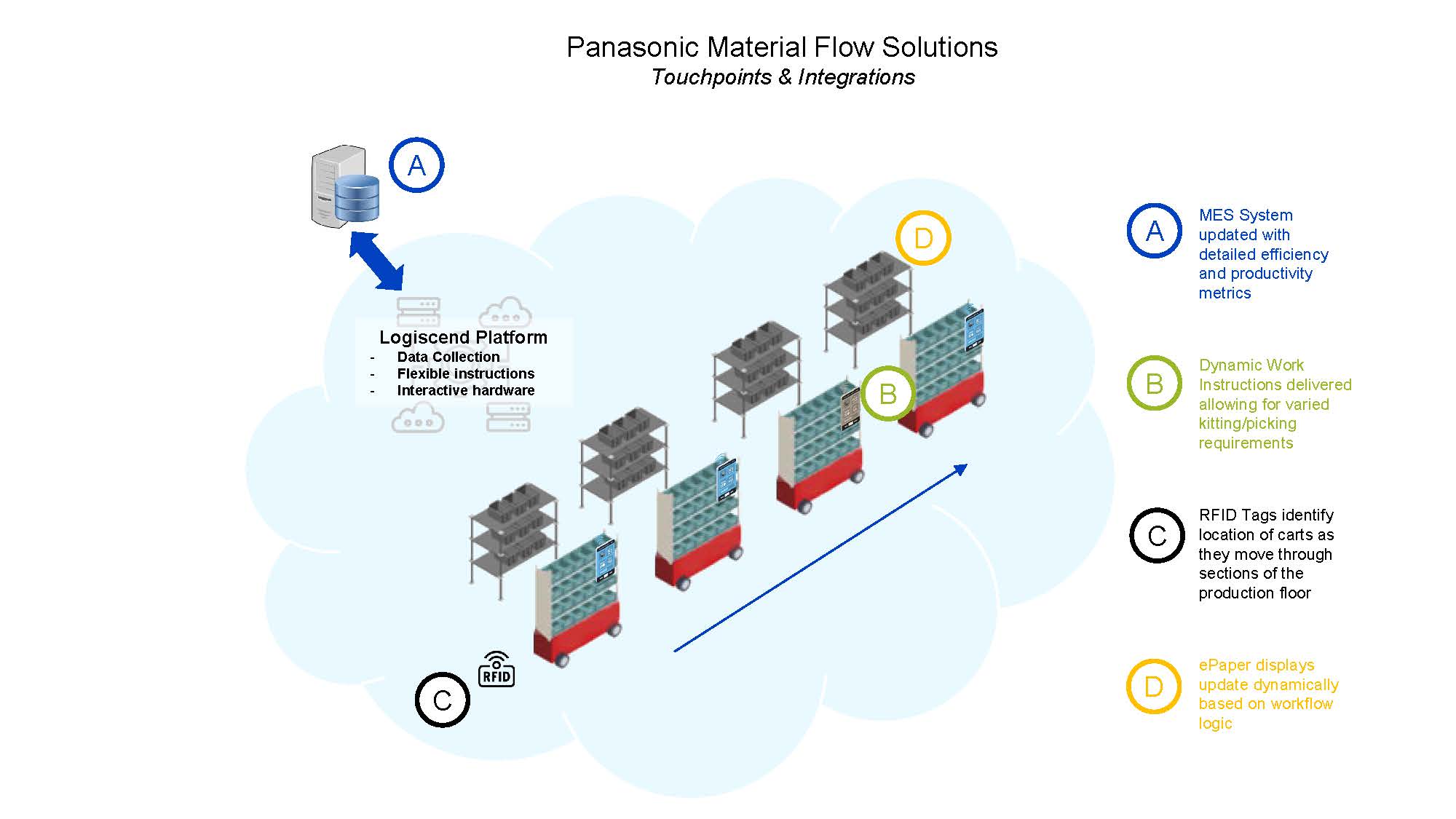

When you are calculating an ROI on an investment in plant automation or digital transformation, the ultimate benefit will be to make your facility more flexible, more agile, and more ready to meet your customers’ demands. The world is shifting to a Just-in-Sequence, Batch-of-One production that you simply cannot achieve without an upgrade in technology. IIoT transformation will not only help you get there, the transparency and the data you will have at your fingertips from the automation technology will allow you to refine your process and incorporate continuous improvement into your workflow that will be dramatic.

The case for immediate payback

That said, if you are looking for an ROI based on more tangible and timely results, possibly with an eye towards building an investment justification to present your case to management, we can help you calculate some of the immediate and significant benefits of an IIoT digital transformation.

Material is expensive!

The first important thing to know about automating and transforming your material flow process is that it will typically reduce your material costs. Material is one of the major costs in most manufacturing operations. So even a small reduction in the cost of materials adds up quickly to a major savings.

The first important thing to know about automating and transforming your material flow process is that it will typically reduce your material costs. Material is one of the major costs in most manufacturing operations. So even a small reduction in the cost of materials adds up quickly to a major savings.

Paper costs more than you think!

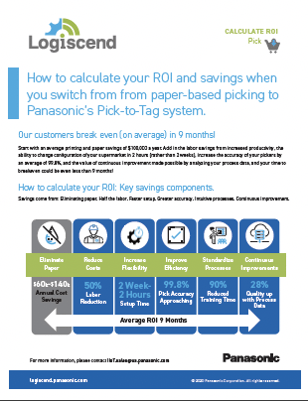

Automating your material flow management means replacing your paper-dependent processes with a digital solution. With the Panasonic Logiscend applications, when you move from a paper-based material flow process to an electronic process the good news is that you can identify an immediate and substantial savings entirely due to the elimination of paper. At Panasonic we have noticed that until our customers add up the cost of paper, printing, stocking, and manpower, customers often have no idea how much they have been spending on paper. The amount you save in a year just by cutting out paper from your picking, kitting, replenishment, work instructions and container labelling functions could easily reach six figures!

Automating your material flow management means replacing your paper-dependent processes with a digital solution. With the Panasonic Logiscend applications, when you move from a paper-based material flow process to an electronic process the good news is that you can identify an immediate and substantial savings entirely due to the elimination of paper. At Panasonic we have noticed that until our customers add up the cost of paper, printing, stocking, and manpower, customers often have no idea how much they have been spending on paper. The amount you save in a year just by cutting out paper from your picking, kitting, replenishment, work instructions and container labelling functions could easily reach six figures!

lIoT material flow is (way) more accurate than paper-based processes

![]() Paper-based Pick results in mistakes. Especially in an environment in which picking or kitting instructions change frequently, the paper trail may not reach the pickers and kitters in time to prevent mistakes. And working off a paper pick list is error-prone, particularly for new employees that don’t have the tribal knowledge that comes with years on the job. Because IIoT instructions are delivered instantly, automation brings an immediate improvement in accuracy—which adds up quickly. Replenishment automation also results in an improvement that is tangible—fewer interruptions to the assembly line, due to having to wait for a needed part.

Paper-based Pick results in mistakes. Especially in an environment in which picking or kitting instructions change frequently, the paper trail may not reach the pickers and kitters in time to prevent mistakes. And working off a paper pick list is error-prone, particularly for new employees that don’t have the tribal knowledge that comes with years on the job. Because IIoT instructions are delivered instantly, automation brings an immediate improvement in accuracy—which adds up quickly. Replenishment automation also results in an improvement that is tangible—fewer interruptions to the assembly line, due to having to wait for a needed part.

The Panasonic applications use proprietary technology (VIEW tags) that provide visual instructions, just as paper does, only because it is e-Paper it is instantaneous. We can help you quantify the value of this increased accuracy and improved quality control.

Training is a major savings

![]() These days, changes are the rule, not the exception. With the Panasonic IIoT material flow, reconfiguring your processes takes hours, not days (or weeks). The wireless VIEW tags are easy to configure with minimal help of IT expertise and without electrical re-wiring. Training is intuitive, because the instructions are visual. So even if your workforce changes frequently, you will spend much less time in training with your digital workflow. We can advise you on how much training you will save based on your operation, but it can be a substantial amount.

These days, changes are the rule, not the exception. With the Panasonic IIoT material flow, reconfiguring your processes takes hours, not days (or weeks). The wireless VIEW tags are easy to configure with minimal help of IT expertise and without electrical re-wiring. Training is intuitive, because the instructions are visual. So even if your workforce changes frequently, you will spend much less time in training with your digital workflow. We can advise you on how much training you will save based on your operation, but it can be a substantial amount.

You will experience a significant savings in labor

![]() Moving away from paper Kanban replenishment, where sharks and water spiders roam the manufacturing floor looking for replenishment signals, your savings will be dramatic. Typically, our customers save at least two FTEs in these processes. And electronically tagging your valuable assets and material will save countless hours searching for “the one.” We can help you identify your labor savings.

Moving away from paper Kanban replenishment, where sharks and water spiders roam the manufacturing floor looking for replenishment signals, your savings will be dramatic. Typically, our customers save at least two FTEs in these processes. And electronically tagging your valuable assets and material will save countless hours searching for “the one.” We can help you identify your labor savings.

Work instructions become much timelier and more accurate with IIoT material flow

![]() When you move from paper-based work instructions to digital, your operators know exactly what they are supposed to build and how to build it. As instructions change you can be assured that the most current version is available in real-time. You can take this a step further by tagging your containers with real-time locators, so the proper work instructions come up when the container arrives at their station. This can add up to a substantial increase in productivity, which we can help you quantify.

When you move from paper-based work instructions to digital, your operators know exactly what they are supposed to build and how to build it. As instructions change you can be assured that the most current version is available in real-time. You can take this a step further by tagging your containers with real-time locators, so the proper work instructions come up when the container arrives at their station. This can add up to a substantial increase in productivity, which we can help you quantify.

When you know where your assets and containers are, you can deploy them more effectively

What’s it worth to know where your inventory, most costly tools, and containers are when you need them? We can help you quantify this, but consider the effect of lost inventory, misplaced tools, or even the reduction in pilferage that comes from 24/7 location information about these assets.

What’s it worth to know where your inventory, most costly tools, and containers are when you need them? We can help you quantify this, but consider the effect of lost inventory, misplaced tools, or even the reduction in pilferage that comes from 24/7 location information about these assets.

You are not alone!

Call us, at Panasonic we can help you with this sort of ROI calculation—most of our customers need to put together an ROI on these applications in order to secure management buy-in on the investment. Fortunately, we have a lot of experience to guide you in this exercise.

Resources

Worksheet

BLE Video

Success Story

Detroit Parts Replenishment